Waste Water Heat Recovery Systems.

Waste water heat recovery systems have had successful usage in the Netherlands for a number of years where they are fitted to more than 20% of new dwellings. They are relatively popular in the UK and are seen as a cost effective way of reaching the Building Regulations.

Instantaneous WWHRS

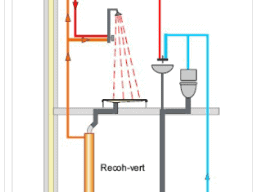

Figure 1 shows a common instantaneous configuration applicable to upstairs showers. The principle of heat recovery is:

- Warm shower water passes through the ‘grey’ water side of a counter-flow heat exchanger.

- Mains pressure water simultaneously passes through the fresh water side of the heat exchanger, where it is pre-heated before passing into both the ‘cold’ inlet of the mixer shower and the ‘cold’ inlet to the hot water cylinder, combi boiler or other water heater.

- The use of pre-heated water (orange line) reduces the total volume of hot water required per shower, whilst also pre-heating the cold feed to the hot water heater which increases potential flow rates for combis or shortens the re-heat time of cylinders. Pre-heating both the shower and the hot water heater.

Figure 1

There are other system configurations, System B and System C. If there are 2 WWHRS systems, the second system must be of configuration System B only, pre-heat of water fed only to the cold feed of the shower. System C pre-heats water to the water heater only and not directly to the shower. The energy saving from the instantaneous WWHRS applies to whichever fuel is used for water heating, and is therefore not limited solely to gas boilers. However, it does not save energy from baths.

Storage WWHRS

There are also storage WWHRS which include an additional combined or separate cylinder. These recover heat from the whole dwelling and do not require simultaneous pre-heated flow and waste. It can therefore recover heat from bath water. Only one system is defined for the whole dwelling.