New Standards for Domestic Boiler Installations – April 2018.

Lisa Blake looks at the Boiler Plus regulations that were introduced in April 2018, and how they affect boiler installations as well as the technologies promoted by Boiler Plus and the difference between an ErP boiler efficiency and a SEDBUK efficiency.

Boiler Plus was implemented on 6 April 2018 and aims to improve the way homes in the UK use energy by increasing the efficiency of their heating systems.

The new standard forms part of the Government’s ‘Heat in Buildings’ programme, designed to maximise energy efficiency. The introduction of Boiler Plus is the first major piece of regulation since the UK went “all-condensing” in 2005 – becoming the first country to do so in the process.

What is Boiler Plus?

The Boiler Plus regulation states that all new boilers installed from April 2018 must have a minimum ErP (Energy Related Products) efficiency of 92%. Note that the ErP efficiency is not the same as the SEDBUK efficiency. New and replacement boilers must also have time and temperature control installed if they are not already present. At a minimum, this means a programmer and room thermostat.

In addition, any new combination boiler must also have an additional energy efficiency measure installed.

What is ErP boiler efficiency?

In 2009, the EU adopted the ErP directive, a framework for setting the efficiency requirements of energy-related products. These are defined as products that use energy or have an impact on energy consumption, such as tyres, light bulbs and boilers. The ethos behind the directive is to reduce carbon emissions across Europe. There are two parts to the directive:

• EcoDesign: ensuring energy-related products meet performance and emissions standards at the point of manufacture.

• Energy Labelling: products should have an efficiency rating from G to A+++, which should be displayed on the product, ensuring end-users are aware of the level of energy efficiency within their products.

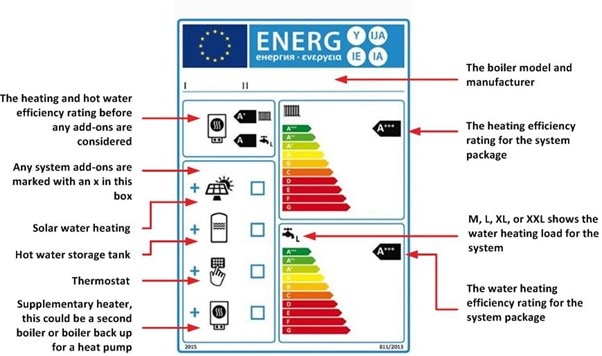

Boiler installers must now create a system Energy Label when they install a new boiler. The energy label gives the whole system (controls, storage, solar contribution and boiler) a rating based on its overall efficiency. To achieve an A rating the system must have an efficiency of over 90%.

How is ErP calculated?

ErP efficiency of a boiler is calculated in a different way to the SEDBUK, which are used for Building Regulations. The current minimum SEDBUK 2009 efficiency for new boilers is 88%, while the minimum ErP efficiency is 92%. So, how do they compare?

We looked at a mains gas combi boiler with a SEDBUK 2009 efficiency of 89.6%, which is compliant with current Building Regulations. The ErP efficiency of this boiler is 94%.

The ErP Data Sheet, which includes all relevant data, including the ErP efficiency should be available for all boilers on the market. The consumer will also have an ErP label on the appliance, which is similar to the energy labels on white goods.

|

| Figure 1 – ErP label for a boiler |

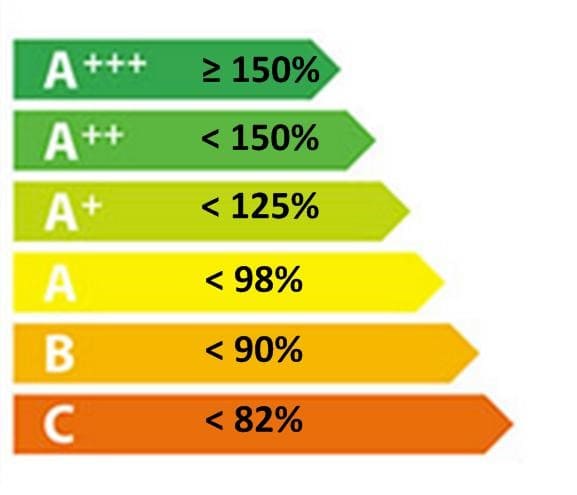

The ErP efficiency bands for water heating are dependent on the hot water load:

| A+++ | A++ | A+ | A | B | C | |

| M | ≥163% | ≥130% | ≥100% | ≥65% | ≥39% | ≥36% |

| L | ≥188% | ≥150% | ≥115% | ≥75% | ≥50% | ≥37% |

| XL | ≥200% | ≥160% | ≥123% | ≥80% | ≥55% | ≥38% |

| XXL | ≥213% | ≥170% | ≥131% | ≥85% | ≥60% | ≥40% |

The ErP system efficiency is the overall efficiency of the boiler and any additional controls or supplements. There is a space heating ErP system efficiency and a hot water ErP water heating efficiency.

ErP System efficiency example

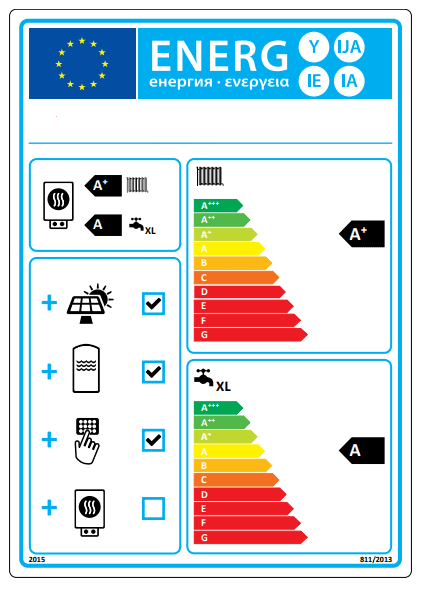

Figure 2 – ErP heating efficiency bands Figure 3 – example ErP system efficiency label | |

Figure 3 shows an example ErP efficiency label, the overall system efficiency is A+ for heating and A for hot water. This would be provided to the consumer when the boiler was installed. This is calculated as follows:

| ErP Efficiency | |

| Boiler (space heating) | 94% |

| Controls | +4% |

| System (space heating) | 98% (A+) |

| Boiler (hot water heating) | 85% |

| Solar water heating | +6% |

| System (hot water) | 91% (A) |

The consumer can see the whole system efficiency with other systems and the impact of good controls/solar water heating. The idea, of course, is that consumers will have a clearer understanding of the benefits of an efficient boiler and the importance of enhancing the efficiency of the whole system with supplementary products.

The Boiler Plus process

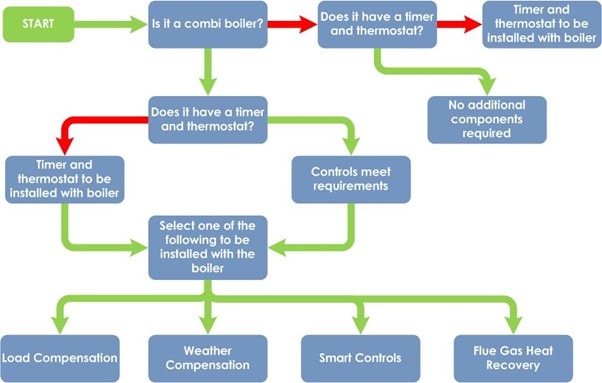

Figure 4 summarises the Boiler Plus process for the installer. Time and temperature controls (programmer and thermostat) must be installed if not already present for retro-fit boilers or new installs. This is the same as current Building Regulations. In addition, if the boiler being installed is a combi boiler, an additional energy-saving measure must be selected. This is over and above current Building Regulations.

Figure 4 – Boiler plus process

Boiler Plus technologies

Load compensation

This is an additional boiler control that adjusts the flow temperature according to the room temperature. When a room is cold, the temperature going to the radiators will be high, but as it warms up, less heat is required. This is when the temperature going to the radiators will be reduced.

This means a gas boiler matches the real heat requirements better than a simple on/off control, reducing energy wastage and maintaining comfort conditions. A condensing boiler works better at lower temperatures and ideally, the water returning to the boiler should be less than 55°C. A load compensator helps to ensure this.

• Benefits: As well as money and energy savings, load compensation reduces wear and tear on the boiler as it minimises short cycling and start/stop operation.

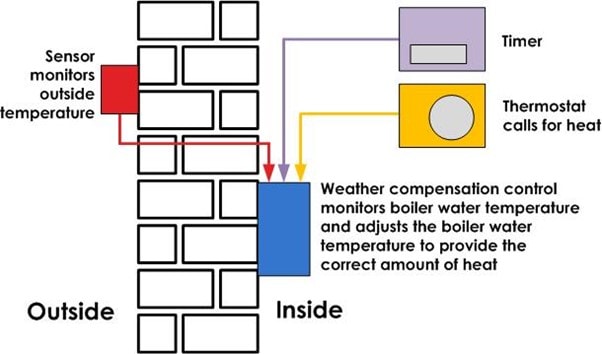

Weather compensation

An additional control for the boiler that adjusts the flow temperature from the boiler according to the outside temperature. In a similar way to the load compensator, this control monitors the outside temperature. When the temperature drops outside, the temperature of the hot water to the radiators will increase. Conversely, when the outside temperature increases, the boiler will supply less heat and reduce the temperature of the water flowing to the radiators.

• Benefits: This is the simplest and easiest of the four options if a room thermostat is already fitted.

|  |

| Figure 5 – Weather compensation sensor | Figure 6 – Schematic of weather compensation |

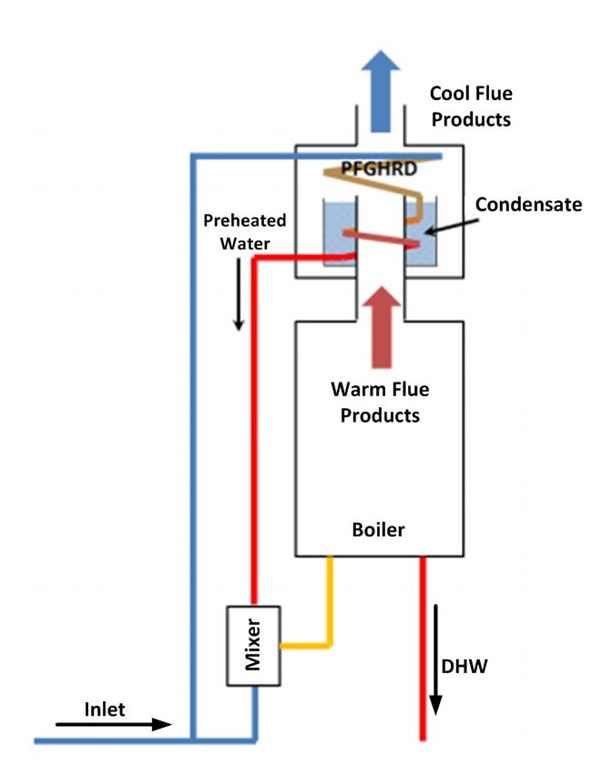

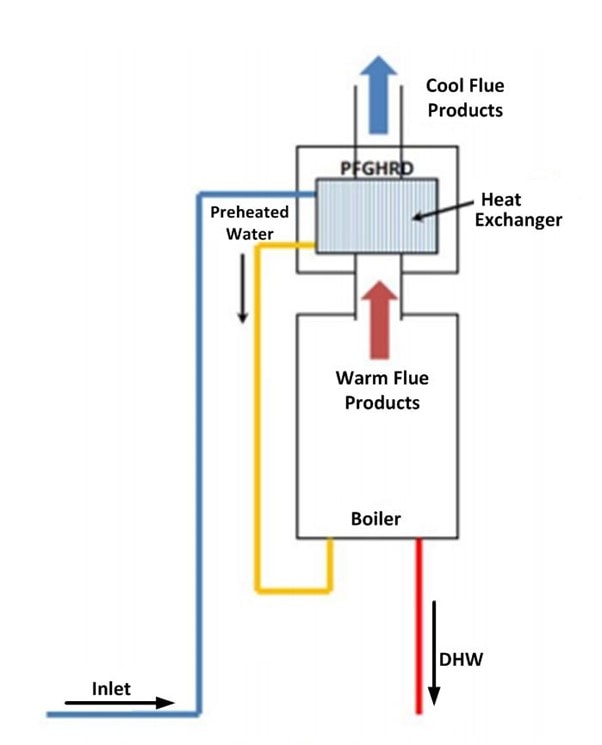

Passive Flue Gas Heat Recovery Device (PFGHRD)

These devices enable users to reuse heat from the boiler that would otherwise be wasted. They are retrofit devices for older boilers that capture waste heat from flue gases and reuse it, to improve the efficiency of hot water production and save fuel and money.

Normally, flue gases escaping to the atmosphere can exceed 60°C. PFGHRD reclaim much of this wasted heat, letting the flue gases then vent to the atmosphere at a much cooler temperature. A heat exchanger is fitted around the flue coming from the boiler to heat up mains cold water that is fed into it. The heated water is then either stored in a tank for later use or used as pre-heated incoming water for the boiler. Flue gas heat recovery has been used with commercial boilers for many years, with energy from the flue gases used to heat the water fed into the heating circuit. This was possible as the boilers were non-condensing and therefore had higher flue gas temperatures. With the advent of condensing boilers and lower temperature flue gases, flue gas recovery was used to pre-heat the domestic hot water. Early (2006) flue gas heat recovery devices often used additional pump or fan energy to recover the heat, more modern devices do not and are therefore considered passive.

• Benefits: These devices can achieve savings of up to 6% on gas usage, you can ‘fit and forget’ and no user input is required.

|  |

| Figure 7 – PFGHRD with store | Figure 8 – PFGHRD with no store |

Further reading: The Government have published some FAQs for consumers and installers, available online here.