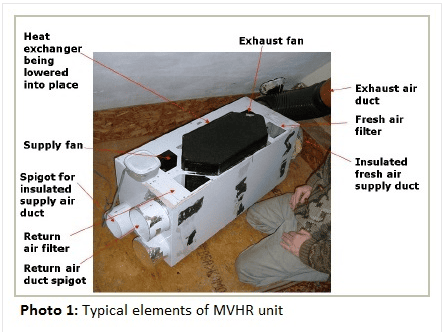

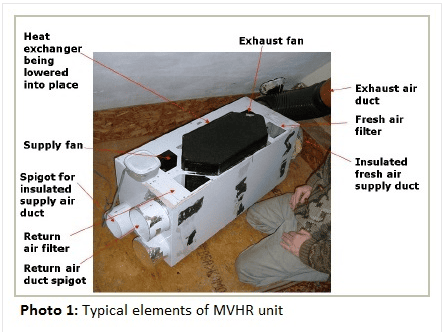

What is MVHR?.

Most MVHR (Mechanical Ventilation Heat Recovery) systems are similar to the prototype unit shown in Photo 1. An insulated duct brings fresh air into one end of the unit. A filter helps to keep the heat exchanger clean. The heat exchanger allows the fresh air to pickup heat across a multitude of thin plastic membranes. A supply fan delivers the warmed fresh air to the insulated supply duct which supplies living rooms and bedrooms. Again a filter keeps the heat exchanger clean and the exhaust fan draws the return air across the heat exchanger and exhausts the air to the outside.

The key things to be aware of when thinking about MVHR systems are as follows:

1. Fan power needs to be low; heat exchanger efficiency needs to be high. Units are now available with efficiencies of 90% and specific fan powers (SFPs) as low as 0.5 W/(l/s). SAP default figures are 66% and 2.0 W/(l/s) (SAP 2012 Table 4g).

2. It is advisable to keep the insulated fresh air duct as short as possible. It is beneficial therefore to position the unit on an outside wall next to the fresh air supply point.

3. The unit should be inside the insulated airtight envelope. Very often the units are shown installed in a cold loft space. This is a bad idea as it will lead to heat losses from the ductwork and the unit itself. Also whenever the ducts pass through the insulated ceiling, the insulation and air tightness will be compromised.

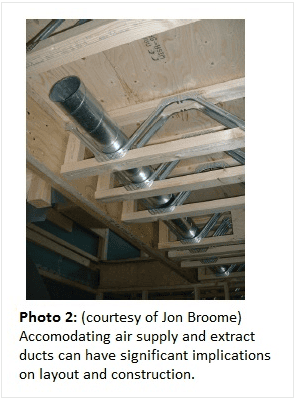

4. Rigid ductwork should be used wherever possible and the duct routes will need to be planned in advance. Flexible ductwork should be kept to a minimum. Photo 2 shows ductwork being incorporated in open web intermediate floor joists.

5. MVHR systems need regular maintenance and heat exchangers and filters need regular cleaning. This will not get done if the units are inaccessible.